Micrometer Screw Gauge

Screw gauge in extensively used in

engineering field for obtaining precision measurements. Micrometer screw gauge

is used for measuring extremely small dimensions.A screw gauge can even measure

dimensions smaller than those measured by a Vernier Caliper.

Micrometer Screw gauge works on the

simple principle of converting small distances into larger ones by measuring

the rotation of the screw. This “screw" principle facilitates reading of

smaller distances on a scale after amplifying them .

Reading A

Micrometer Screw Gauge

Step 1 Turn the thimble until the anvil and

the spindle gently grip the object. Then turn the ratchet until it starts to

click.

Step 2 Take the main scale reading at the

edge of the thimble

Step 3 Take the thimble scale reading

opposite the datum line of the main scale. Multiply this reading with least

count i.e., 0.01mm

Step 4 Now add main scale reading to thimble

reading. This will be the diameter of the object.

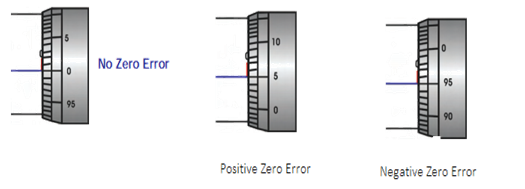

Zero Error

of a Screw Gauge:When

the plane surface of the screw and the opposite plane stud on the frame are

brought into contact, if the zero of the head scale coincides with the pitch

scale axis, there is no zero error.

Positive

Zero:Error When the

plane surface of the screw and the opposite plane stud on the frame are brought

into contact, if the zero of the head scale lies below the pitch scale axis,

the zero error is positive.

Negative

Zero Error:

No comments:

Post a Comment